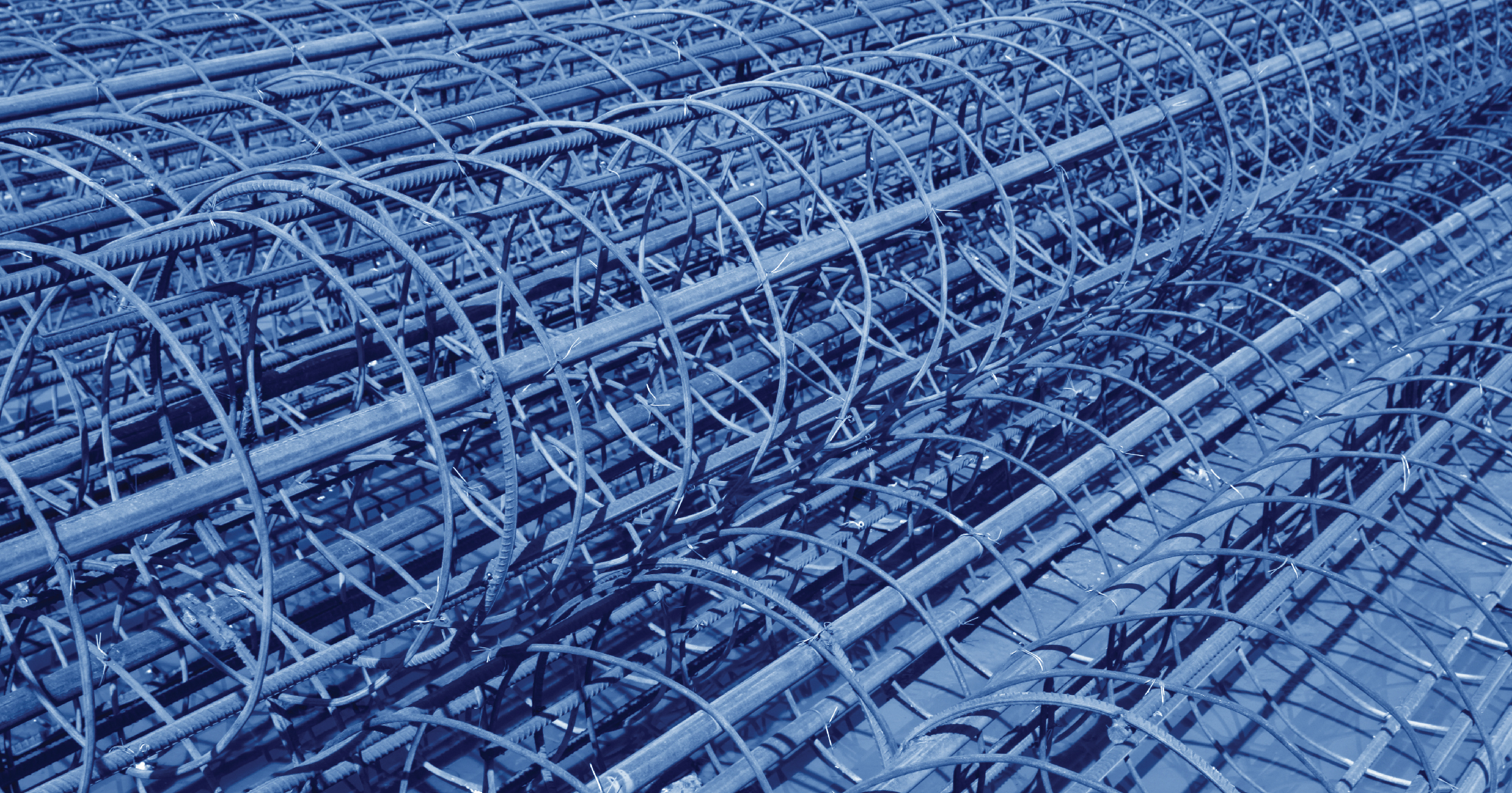

In the construction domain, the choice of materials plays an important role in ensuring the structural integrity and longevity of a building. One such material that has gained significant recognition for its superior properties is Fe 550 TMT (Thermo-Mechanically Treated) bars.

Let’s delve into the advantages of using Fe 550 TMT bars in construction projects.

Uses of Fe 550 TMT bars in construction projects:

Strength

Fe 550 TMT bars are known for their exceptional tensile strength making them the best choice. Their ability to resist deformation under stress ensures the structural stability of buildings, even in adverse conditions.

Ductility

TMT bars offer an excellent balance between strength and ductility. Their ductile properties allow for controlled deformation, which is crucial in absorbing and dissipating energy during earthquakes or other dynamic loads.

Corrosion Resistance

Fe 550 TMT bars are coated with a protective layer that shields them from corrosion. This feature extends the lifespan of the bars and, consequently, the entire structure they support.

Cost-Effective

Although Fe550 TMT bars pricing is little higher compared to the conventional reinforcement bars, their enhanced properties results in long-term cost savings through reduced construction and maintenance costs .

Ease of Handling and Welding:

TMT bars are lightweight and easy to handle, which simplifies the construction process. They also have excellent weldability, ensuring secure connections between bars during construction.

Reduced Construction Time:

Due to their high strength and ease of use, Fe 550 TMT bars can accelerate the construction. This results in shorter project durations and reduced labor costs.

Sustainability:

Using Fe 550 TMT bars can contribute to sustainable construction practices. Their durability and resistance to corrosion reduce the need for replacements, thus reducing waste and environmental impact. Compliance with Standards: Fe 550 TMT bars abide by industry standards and specifications, to meet the safety and quality requirements of the construction project.

Conclusion:

The advantages of using TMT bars significantly enhance structural integrity, provide superior strength, ensure ductility, corrosion resistance, and cost-effectiveness. The ease of handling and welding, coupled with their contribution to reducing construction time, make them a preferred choice for builders and engineers alike. As the construction industry continues to evolve, Fe 550 TMT bars stand as a testament to innovation, safety, and sustainability, paving the way for safer and more resilient structures in the future.

Fe 550 TMT bars have emerged as a game-changer in the construction industry, and Kalinga TMT stands out in competition with its advanced grip technology and is the most popular and preferred choice of the builders.

1. Are you looking for the best TMT bar manufacturers

Kalinga TMT stands out as a premier manufacturer of TMT steel bars in South India, specifically renowned for their exceptional quality and reliability. With an unwavering commitment to delivering excellence, Kalinga TMT has established itself as a trusted brand in Hyderabad, excelling in the production of Fe 550 TMT bars. Their market positioning is characterized by a harmonious blend of superior quality, exemplary service, and competitive pricing, solidifying their status as one of the most reliable manufacturers in the industry.

2. Are Fe 550 TMT bars suitable forearthquake-prone areas?

Fe 550 bars undergo stringent testing through a series of reverse-loading pressure tests thus guaranteeing exceptional strength and flexibility. Care is also taken to maintain the UTS/YS ratio (Ultimate Tensile Strength and Yield Strength ratio) and conduct Percentage Elongation testing. This ensures that the Fe 550 bars are well-equipped to withstand the seismic activity and demanding loads prevalent in earthquake-prone areas